Semi-auto Finger Jointing line

Application

Finger jointing is recognized as the most stable method of creating length joints between two solid wood or wooden composite components. It is used in order to produce very long wood components or to separate out knots and cracks which lower the strength. Using finger joints it is possible to joint short pieces of wood into one, in principle, infinitely long strand of wood.

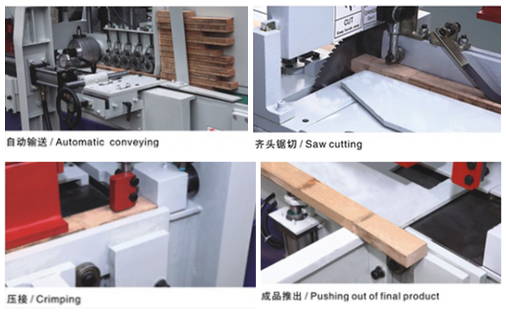

Our finger joint line, offers a particularly workable solution for length joints processing for both vertical and horizontal finger joints ,with belt conveyor, finger joint shaper (with glue), roller conveyor, chain conveyor, using extremely user-friendly , easy-operated, noise-free system to achieve high precision effect

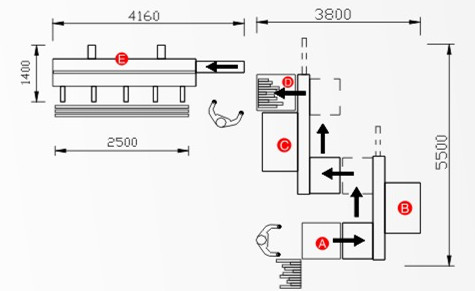

Layout

A- Belt Conveyor

B- Automatic finger joint shaper

C- Automatic finger joint shaper (with glue)

D- Roller conveyor

E- Automatic finger joint press

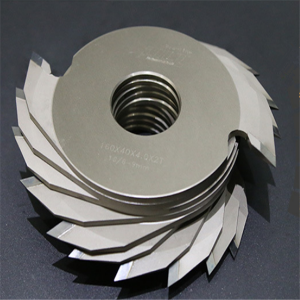

Machine Lathe

Model details

Technical Parameters

|

Semi -automatic Finger Joint Line |

KC150A |

|

Wood entry length |

150-900mm |

|

Shaping wood thickness |

20-150mm |

|

Cutting table width |

450mm |

|

Wood width |

20-80mm |

|

Wood thickness |

30-150mm |

|

Shaper spindle dia. |

Φ50mm |

|

Shaper rotary speed |

6750r.p.m |

|

Hogger spindle dia. |

Φ30mm |

|

Hogger rotary speed |

2840r.p.m |

|

Max. Wood exit length |

2500mm |

|

press force |

7500kg |

|

Shaper spindle power |

11kw X 2 |

|

Hogger power |

4kw X 2 |

|

Scoring power |

0.75kw X 3 |

|

Hydraulic system power for Press |

4kw |

|

Saw blade power for Press |

4kw |

|

Belt conveyor power |

0.75kw |

|

Roller conveyor power |

0.75kw |

|

Total Power |

41.75kw |

|

Working air pressure |

6-8 bar |

|

Wind Measure of dust collector |

9000m3/h |

|

Machine Dimension |

8000x6000mm |

Workshop

Packing & Loading

Operation Video