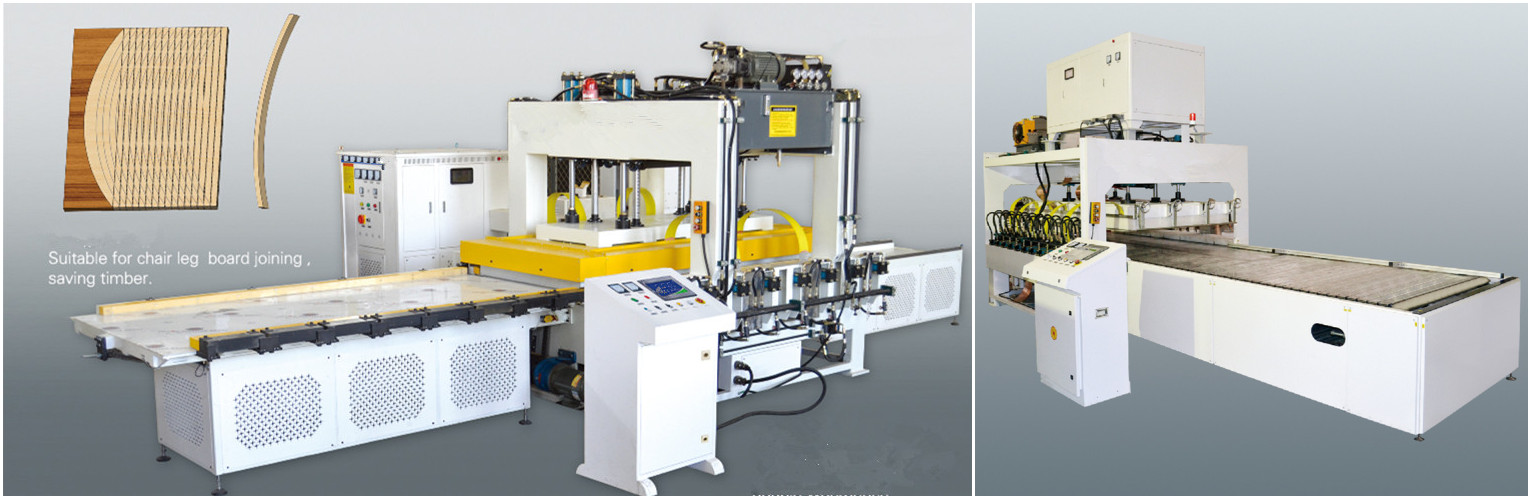

High Frequency board jointing machine (Vertical Lifting)

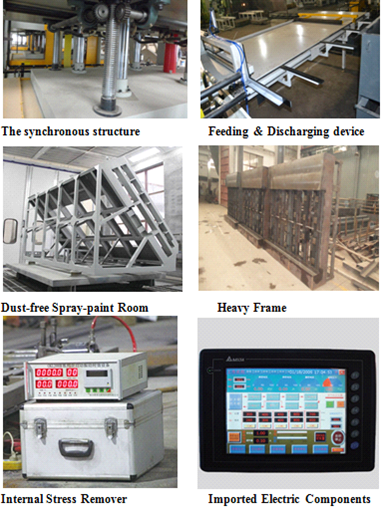

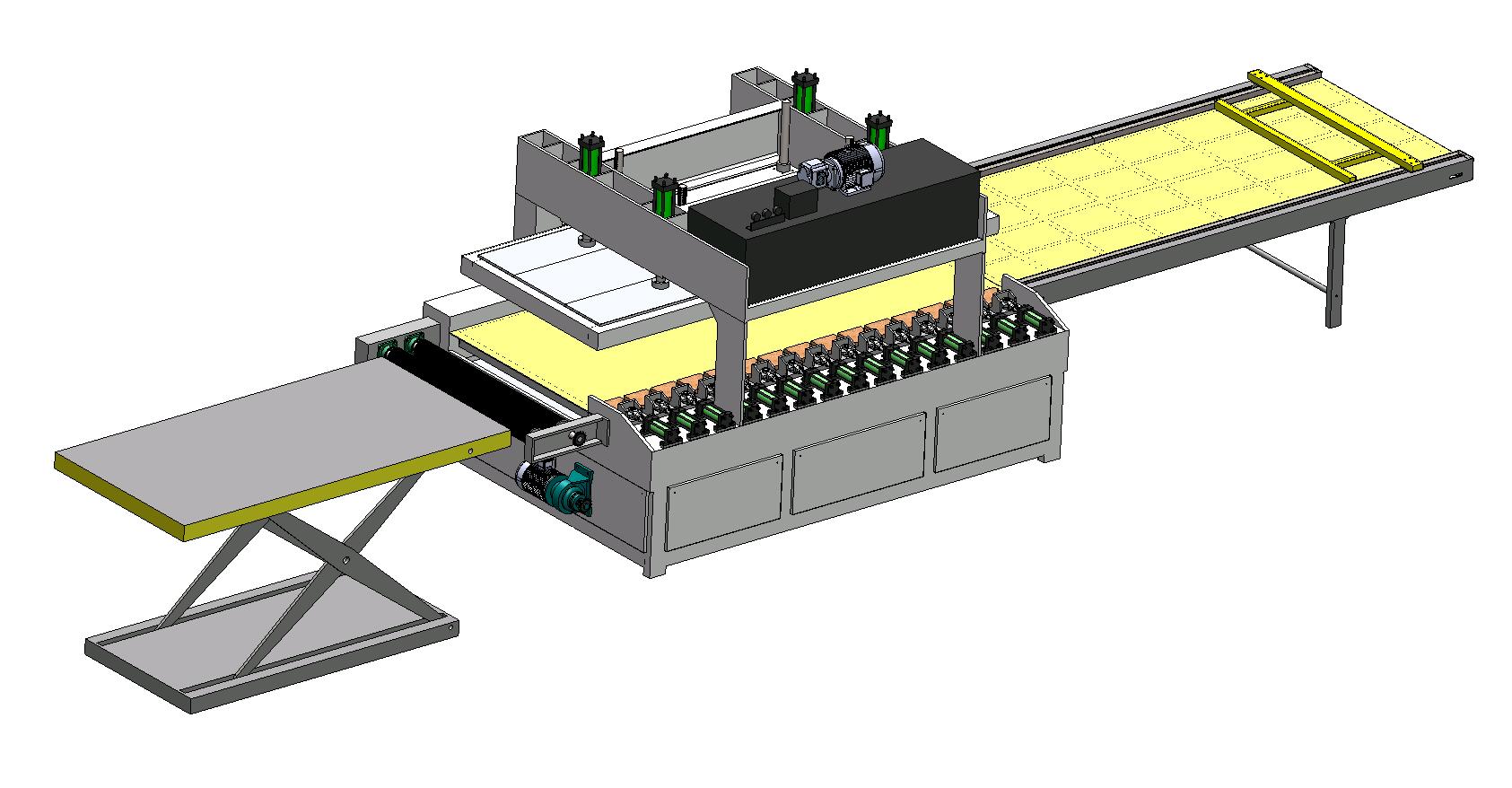

Our HF board jointing machine ( vertical lifting ) , which is the updated version of high frequency board jointing machine, with upper plate adopts vertical lifting and installs the synchronous system, so as to achieving higher planeness, saving 0.3mm plane thickness .

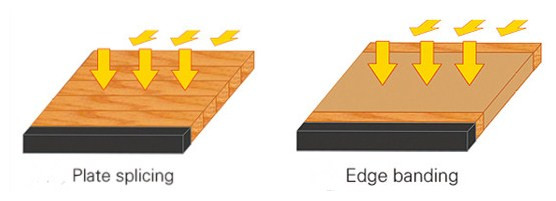

Application

It mainly apply to laminated wood, particle board, door panel jointing, and solid wood, door pocket, door line banding, or other wooden block gluing etc.

Model Features

1. High Timber Outturn : 5%-10% more on average compared to the general clamp carrier

2. High Efficiency : 1-3 mins to finish one board , 15-20 seconds shorter than horizontal board joining , efficiency improved 5%-7%

3. Energy Saving : 15-30kw/h power consumption for 1cbm board jointing

4. Low Labor Cost : feeding & discharging device of belt-conveyer , adding palletizing and gluing system for option to get more efficient as well

5. Heavy Frame : Using large-scale machine tool to ensure its verticality

6. Easy Operation: Touch screen HML, with a built-in operation instruction which including installation, operation, repair, maintenance etc.

7. Safety : Adding high sensitive spark protection circuit and make separated cabinet for HF parts

8. Good components : assorting Taiwan pneumatic tools mostly

9. The thinnest board of jointing is 6mm at least

Model Details

Technique Data

| Type | KCPB-50PZ | KCPB- 61PZ | KCPB-70PZ | KCPB-120PZ |

| Workbench size (mm) | 2500×1300 | 2500×1300 | 3000×1300 | 6000×1300 |

| Jointing thickness (mm) | 6-50 | 6-80 | 8-80 | 8-80 |

| Vertical pressure (T) | 28 | 28 | 28 | 42 |

| Horizontal pressure (T) | 22 | 33 | 42 | 78 |

| Overall size (mm) | 8700(L)×4400(W)×2300(H) | 8700(L)×4400(W)×2300(H) | 10200(L)x4400(W)x2300(H) | 18200(L)x5200(W)x2400(H) |

| Weight (T) | 5.5 | 6.5 | 7.5 | 13 |

| Feeding | Auto | Auto | Auto | Auto |

WorkShop

Case for referance

Optional device

—– Automatic palletizing system

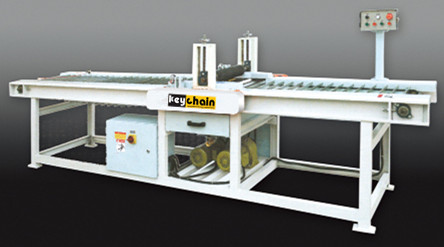

—- Chain type Glue Applicator

Which is suitable for gluing single surface during glue-laminated board production , the chain conveyor system adopts zigzag framework ,which greatly assure the gluing quality .

| Model No. | TJ-400-L |

| Max gluing width( mm) | 400 |

| Dia. of gluing roller (mm) | Φ130 |

| Gluing roller quantity | 1 |

| Gluing roller speed (m/min) | 10 |

| Feeding motor power(KW) | 0.75 |

| Gluing motor power (KW) | 0.4 |

| Machine overall size( mm) | 920(W)*3600(L)*1320(H) |

| Machine weight ( KG) | 700 |

Series Models

Double workbench HF board jointing machine & Crewle stype HF board jointing macine

Full automatic HF board jointing machine production line ( including gluing system )

Operation Video