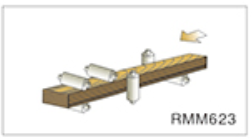

M623 High Speed Four Side Moulder

Application

Our four side planer with different working width 120mm, 160mm, 200mm, 230mm , and with different spindles ( four, five, six ) for different workpiece demand . Which is a good professional solutions for wooden floors, door frames, stairs handrail, skirting line, various wooden lines and the big cutting quantity processing

Model Features

1.Inverter feed speed of 6-30m/min (Optional feed speed 9-45m/min)

2.Individual motor to each spindle to ensure maximum power transmission

3.High precision spindle units with two pairs of high precision bearing each end of assembly

4.All main spindle adjustments are carried out from outside the enclosure

5.Electroplating worktable, good wear resistance

6.Sort piece driven top feed roller unit for greater feeding control around the right side spindle

7.A group of side pressure wheels on the right side of the left spindle, adjusted the pressure flexible by pneumatic

8.As our standard, short pieces device with pneumatic double-direction (press and raise), you can make the workpiece feeding or back at any time

9.In-feed bottom helical roller is more suitable for large deformation and high moisture of the wood to feed

10.Multi-group bottom driving roller to improve the feed effect

11.Pneumatic pressure loaded to top feed rollers separated adjustable, for easy of feeding stock with variation in thickness

12.Adjustable out-feed side pressure plate can meet the different thickness of material output steadily

13.Manual bed lubrication to reduce friction and improve feeding difficult timbers

14.Adopting electric component from international class with steady quality

15.Sealed safety enclose to reduce noise levels, improve extraction and operator safety

Parameter

| Model No. |

M623 |

||||

| Working width | 20-230(mm) | Basic motor power | first bottom spindle | 5.5kw/7.5HP | |

| Working Thickness | 8-160(mm) |

|

first right side spindle | 5.5kw/7.5HP | |

| Numbers of spindles | 6 |

|

first left side spindle | 5.5kw/7.5HP | |

| Spindles speed | 6000r/min |

|

first top spindle | 7.5kw/10HP | |

| Cutting circle | first bottom spindle | Φ110-Φ145 |

|

second top spindle | 5.5kw/7.5HP |

|

|

first right side spindle | Φ110-Φ200 |

|

second bottom spindle | 7.5kw/10HP |

|

|

first left side spindle | Φ110-Φ200 |

|

feed | 5.5kw/7.5HP |

|

|

first top spindle | Φ110-Φ200 |

|

feed beam rise & fall | 0.75kw/1HP |

|

|

second top spindle | Φ110-Φ200 | Total motor power | 43.25kw/58.5HP | |

|

|

second bottom spindle | Φ110-Φ200 | Feed speed | 6–30 | |

| Spindle diameter | Φ40 | Dust outlet diameter | Φ150 | ||

| Weight | 4600kg | Machine Overall size | 4660x1720x1730(mm) | ||

Operation Video