1000mm Wide Belt Sander

Application – HEAVY DUTY WIDE BELT SANDER

This machine is a standard sander,which is used for the thickness calibration of short working piece in the furniture, wooden door and cabinet.The sanding thickness is from 2.5mm to 160mm. The flatness and surface perfection are national standard and applying requirement.

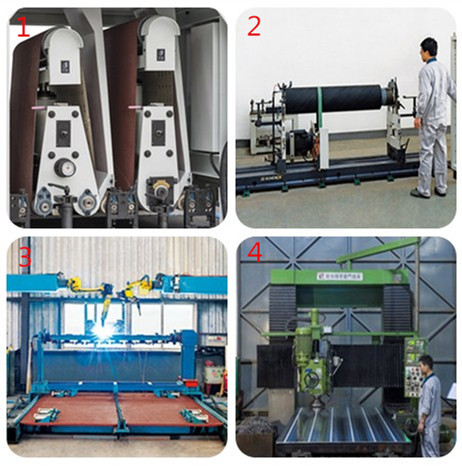

Model Details

1) Rational structure design

2) Dynamic balance test

—Rollers tested by dynamic balance machine

—Calibrating precision from 1g to 3g

3) Mechanical welding

—Automatic welding by mechanical hand

—Heat treatment

—Base made by high quality steel

4) Conveyor table surface

—Mirror finishing

—Flatness within 0.05mm

—Heat treatment by high temperature

5) Bearing

—SKF bearing

—Higher precision

—Easy maintenance

6) Conveyor belt

—Rhombus design

—Stable running without vibration

7) Electric components

—Brand Siemens

—Quality guarantee

8) PLC

—-Brand DELTA

—-Widely used in all electric controller

9) Photo eye

—BANNER imported from American

—Super penetrability

10) Gearbox

—High quality gearbox with inverter motor

Model Features

1.Suitable for the sanding surface of furniture, door and window, and fine polish of solid wood line, plywood, particle board and block board.

2.Sander base adopts high-quality steel, welded by robot automatically. Weld joint is stable and no deformation after heat treatment.

3. The surface of conveyor table is processed by mirror finish with high flatness. It is stable, no deformation and high precision.

4.Tested by dynamic balance, the calibration precision of roller is within 1-3g, 20% higher than the national standard. It can improve the sanding precision and avoid S-shaped grain.

5. Equipped with up and down adjustable device, segmented press boards adjust the position and pressure of roller according to different boards, to ensure the effective guiding.

6. Integrated sanding roller with triangle belt, performance and structure are stable and maintenance is easy

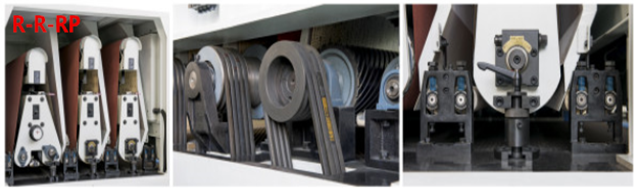

Other Combination : ROLLER+ROLLER+COMBINATION

|

1) Processed data |

Working width: 40-1000mm |

Working thickness: 2.5-150mm |

|

|

2) Sanding roller diameter |

First roller φ240mm |

Second roller φ210mm |

|

|

3) Running speed |

Conveyor belt: 0-19m/min(inverter) |

First roller: 24m/s |

Second roller: 18m/s |

|

4) Size of belt |

Sanding belt: 1030x2200mm |

Conveyor belt: 1000x3700mm |

|

|

5) Motor power |

Total motor power: 55.62kw |

||

|

First belt motor: 30kw |

Second belt motor: 62kw |

||

|

Feeding motor: 3kw |

Lifting motor: 0.37kw |

Brush motor: 0.25kw |

|

|

6) Size (mm) |

Overall size: 2300*2350*2120 |

||

|

7) Weight |

About 3450kg |

||

|

8) Others

|

Working pressure: 0.4-0.8Mpa |

Compressed air consumption: 1m³/min |

Average speed of sucked air: >30m/s |